Blog

Blog

What savings does the mechanical separation of slurry entail?

05th November 2019 - Studies

Óscar Toledano. Marketing and BI Manager.

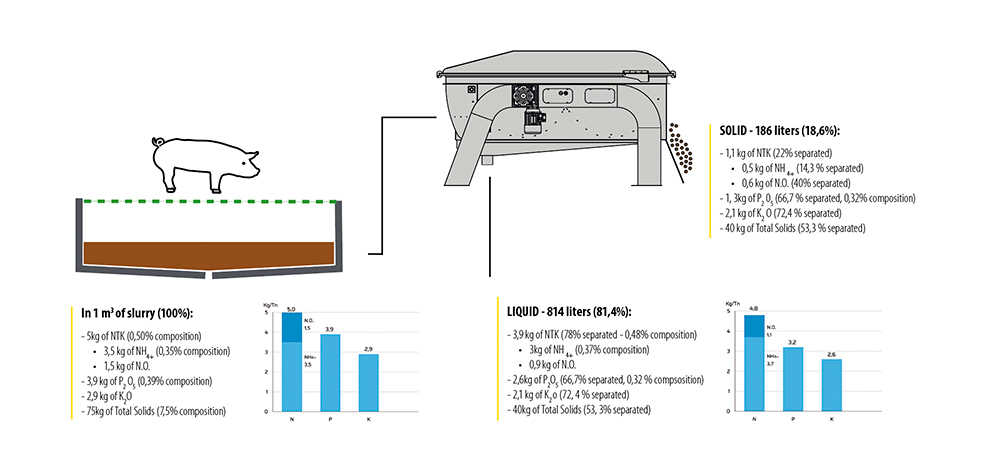

The comparative analyses between the initial slurry compared to the liquid and solid phases segregated during the operation analysed, show the advantages offered by mechanical separation as it improves the application and fertilising qualities of the slurry. Besides, it has economic benefits that make the separator an excellent investment.

Liquid phase

We reduce the volume of liquid slurry to be transported by 19% (estimated application cost of 2.00 €/m3).

We reduce the total Kjeldahl nitrogen content by 4% (NTK, from 0.50% to 0.48%), thus increasing the amount of slurry that can be applied per hectare in fertilisation with nitrogen. However, the proportion of inorganic nitrogen (NH4+, ammonium) also increases by 6 % (from 0,35 % to 0,37 %), which is what the plants absorb directly, so we significantly improve the fertilisation coverage (done on newly born crops, when their nitrogen needs are at their peak).

The phosphorus composition is reduced by 18% (P2O5, phosphate, from 0.39% to 0.32%), so we minimise the amount of phosphorus supplied per unit of nitrogen.

The absence of large solids is ideal for application by hose or injectors; thus, it is applied homogeneously and reduces the time and cost of implementation.

Solid-phase

We generate a compostable solid of high added value with a high concentration of nutrients, especially organic nitrogen (NO) and phosphate (P2O5), which make it ideal as a base fertiliser (which is applied to the crop before planting). After a composting process of three to six months, which involves a mass reduction of 50%, it can be sold as an organic fertiliser at a market price that, depending on the area, ranges between 10 and 20 € / T.

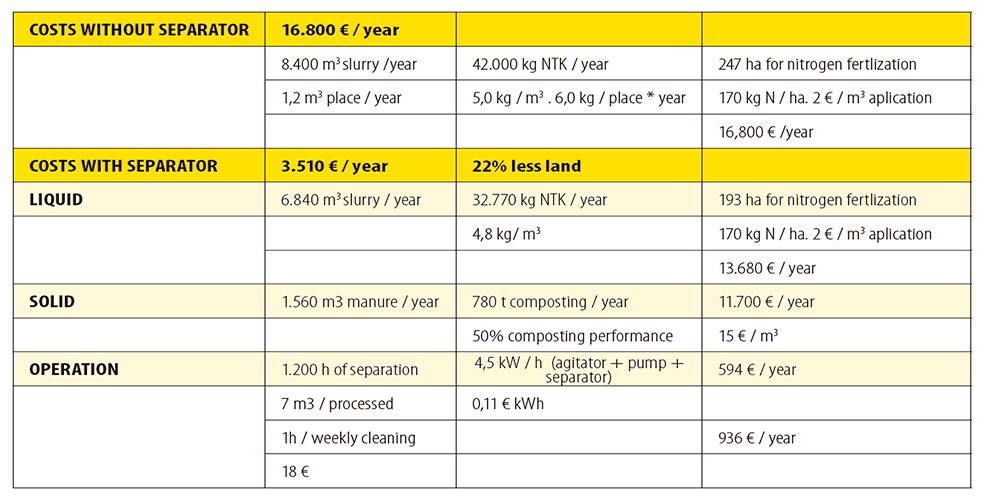

If we extrapolate these data to a typical farm of 7,000 fattening spaces from 20 to 110 kg, we obtain the results represented in the following cost table.

Conclusion

With a mechanically separated slurry application at 170 kg N/ha (maximum for an exposed area with winter cereals), we would need 193 ha of land instead of 247 ha. This whole process would mean an annual application, operation and maintenance cost of 15,210 € instead of 16,800 €, and a profit of 11,700 € would be generated from the compost sale.

Overall, this results in a saving of around 1.90 €/seat/year to repay the installation cost and requires 22 % less land for the management of liquid slurry.

Separation becomes popular as the main slurry retrieval system

Two years after its launch, the TecnaPur solid-liquid separator has become a highly efficient product for the treatment of slurry due to its performance, low operating costs and benefits.

Livestock farmers all over the world are now investing heavily in this technology to process their animal excrement, turning a problem into a benefit and boosting the economy.