Blog

Blog

J. Corsa: “With Evofeed we reduce diarrhoea problems in piglets"

09th September 2020 - Success stories

Coming from a family committed to agriculture and livestock, Jordi Corsa decided from a very young age to continue with the family tradition and take charge of the business together with his brother. Over the years and facing the good figures of other farms owned by Cal Romano, the brothers went for diversifying their business in the pork sector and building a weaning farm, which they launched last October. Furthermore, their concern for modern and technical facilities made them invest in electronic power with Rotecna’s Evofeed multiphase power control system. In this interview, Jordi explains how weaning is handled with this program.

When and why did you decide to commit yourself to pork farming?

I decide to become a farmer when I am very young. It is a family business. At home we have always devoted ourselves to agriculture and livestock, so, over time, I and my brother have continued the tradition and we are the ones who now manage the farms and the fields.

What is the origin of this weaning farm?

This is a new farm for us. Until now we only had pig fattening, but we thought about expanding and investing in weaning. It was a way to diversify business within the pork sector. Besides, after deciding to make the investment we also went for having a more modernised farm.

How is the installation distributed?

We have three independent rooms. In each room, there are between 2.000 and 2.400 animals, distributed in 24 large pens. Then, we also have 6 small pens that we use as sickbays. In all these rooms, we work with the “all inside - everything outside” system to guarantee maximum health. On the other end, we have a dressing area and an office.

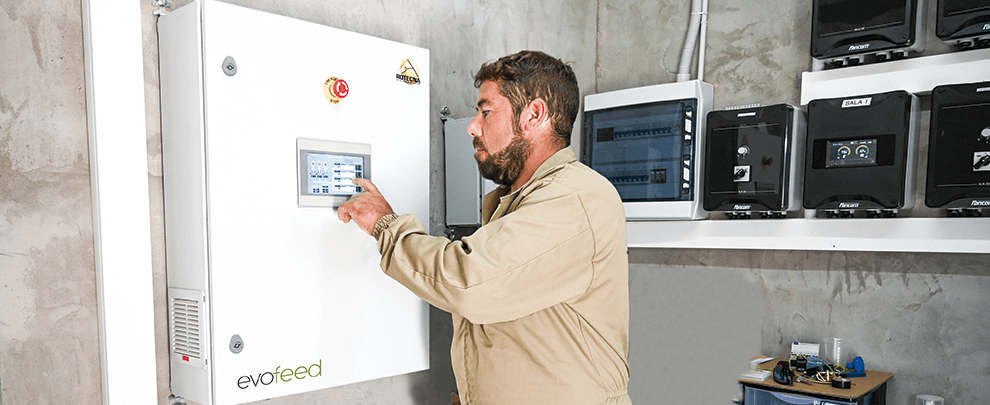

Jordi in his farm. Photo: Rotecna.

Who works on the farm?

One of the two brothers works on the farm, since we divided the tasks between this farm and the fattening one, and we also have a person who takes care of daily work.

When you chose to install the Evofeed multiphase power control system on the farm, what needs did you intend to cover?

We decided to install the Evofeed system because it allows us to control the feed supply very efficiently and we can make all the premixes and mixtures that we want with the feeding curves that our Cincaporc technicians (integrator which we work with) decide, etc. Also, it is a very comfortable system to manipulate and control.

Why did you go for Rotecna’s system?

We saw that it was impossible to supply a perfect mix of feed and the day we wanted with other systems on the market; instead, with the Evofeed we achieve perfect blends with the exact amount of kilos of feed that we set and the days that we program. We have also been working with Rotecna and its products for many years, and our trust in the company is total.

How do you work with this power control system?

We have three outer silos that store three different types of feed with a machine for each silo, which is the one that supplies the food to the farm. On the other hand, within each room, we have a separate machine that is the one that serves the predetermined mixture to the pens. We control the entire feeding system using a digital screen where we can see the feed that we manage per room with the mixtures. From here on, what we do every day with Evofeed is control it. Every morning, upon arrival, we check the feed weight and the mixtures that have been supplied on screen, to verify that everything has worked correctly, and we quickly check the pens to see the state of the animals. The truth is that Evofeed is designed so that you do not have to do anything else in the weaning rooms.

How transitions are scheduled in the system?

The mixtures we have are determined by the company’s technicians we work with. Specifically, a type of feed is supplied the first 10 days of the piglets’ entry, then the mixtures are made, after 20 days it is changed to the second feed, the mixture is carried out progressively again until the last feed is delivered. The entire process is always supervised by the integrator.

After a few months of use, what are the main advantages Evofeed offers you?

Precise control in feed supply and blends. Even when supplies are down to half, we can make a variation in the mixtures that we want to distribute. Also, we have verified that with Evofeed we greatly reduce diarrhoea problems in the piglets, since performing the mixtures well is very important, because it means avoiding digestive problems in the animals with them feed transitions. In this way, we have less diarrhoea and less significant weight drops in animals, which is transformed into better kilo/piglet conversions and better farm health overall.

At the work organization and management level, what are the advantages?

Being an automated system, in which nobody has to supervise the feed or quantities mixtures and premixes, we have significant cost savings in personnel and time. Keep in mind that with traditional management systems, feed control is very poor, since it is visual and approximate. With Evofeed, feed is controlled by the gram and is extremely accurate.

It is easy to use?

It is a very easy to use system, any operator can manage the computer program. In short, Evofeed is a comfortable, very reliable system and all the premixes of feed we make are easy to control and understand for everyone (for the owner, the operator and any technician who comes).

Pen with TR4 hopper, slats and dishes installed. Photo: Rotecna.

What other Rotecna products have you installed?

Virtually everything we have installed on the farm is from Rotecna; slats, hoppers (TR4 and Swing R3), old dishes, PVC fences, feed distribution system...We have had a very good relationship with Rotecna for many years. They supply us with practically all the material for the farms. Until now we have always worked with them with baits and now also this weaning. A good thing about Rotecna is its commitment to innovation, that is why we are testing the new products it launches as they always represent an improvement.

What future challenges arise?

As in any weaning farm, our main challenge is to improve conversions and the health conditions to avoid health problems.