Blog

Blog

Discover all the advantages of the Rotecna SF3D fattening feeder

20th January 2022 - Success stories

Willing to continue with the family tradition, Jaume Alòs decided to take the reins of the farm that his grandfather built more than 70 years ago in the municipality of Almenar. Although they only had some sows and cows in the beginning, with the incorporation of their father to the business, the farm specialised in pig production and, little by little, increased its capacity. Years later, Jaume joined the team, opted for professionalisation and innovation, and introduced systems capable of optimising the operation of the facilities to be more competitive within the sector. In 2020, Jaume completed the last expansion of the farm with a new fattening shed with a capacity for 1,000 pigs. In the new room, it has the SF3D feeder from Rotecna and the polypropylene separator panels.

Why did you decide to become a farmer?

For me, livestock farming is a family tradition that my grandfather started, and my father followed along with my mother. Seeing how they worked, I got that passion that they had for animals. At 19, I began to give myself entirely to working on our farm, first helping my father, who was in charge of the management, until the moment of his retirement, when I stepped forward and took the reins of the business. Then I thought it was necessary to make some changes to be more competitive, and in 2013 we made the first expansion in the sow’s nucleus and hired staff outside the family. In 2020 we carried out a new addition in fattening and reached 1,600 pigs.

How is the farm distributed?

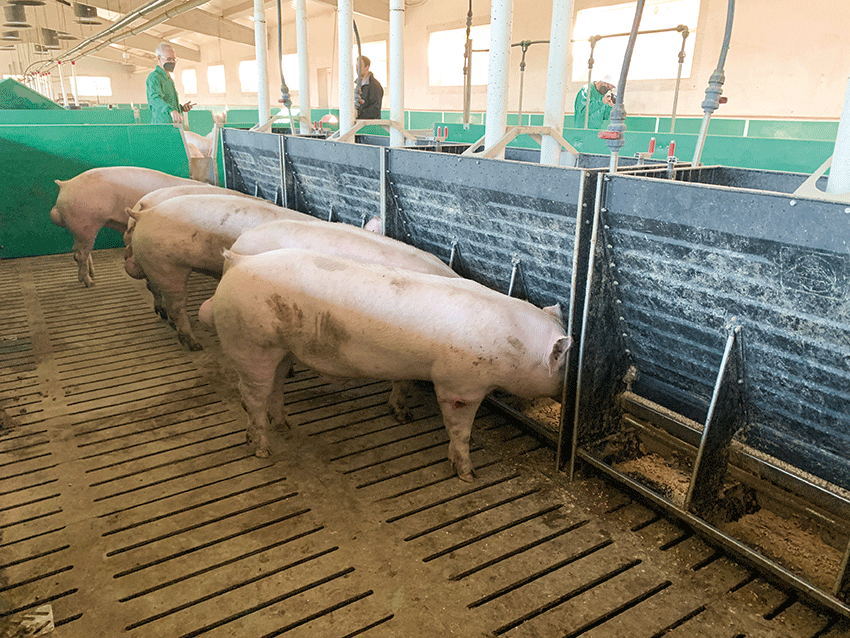

Our farm consists of a centre where the sows are (quarantine, gestation and maternity warehouses), weaning and a small part of the fattening. Then, we have three more fattening cores, one of our properties with a capacity for 1,600 pigs, another integrated one with 1,500 animals, and another on a rental basis with 460 fattening and weaning places. In the last warehouse we built, which is in the first fattening core, we have two large pens, with a capacity for 500 pigs each, and with an individual weighing system that refers each pig to the area of the pen where the quantity and quality of feed appropriate to its weight are offered.

Image of the new fattening shed built on Jaume’s farm with capacity for 1,000 animals, 500 pigs per pen. Photo: Rotecna.

How many people work on it?

Our staff is made up of three employees, my wife and I. Of these three people, two are exclusively responsible for the nucleus of sows, with their weaning and fattening, and the third person serves as a wildcard and help in the rest of the areas, in the other cores, in anything that may be needed.

Why did you decide to install the SF3D feeder?

Mainly because its characteristics answered two fundamental needs for us; first of all, because the SF3D is a large capacity hopper, which allows us to serve a large amount of feed; this was a requirement since having such a large batch of animals, we needed the hopper to have enough capacity so that the pigs can eat what was necessary with two fillings a day. Secondly, we decided on the SF3D hopper because it allows us to feed the pigs in two different ways: in the lower tray, they can take the feed with some water, while in the upper tray, they can eat the dry feed. This offered us an added advantage, as any pig from such a large batch can decide how to eat and feed.

What benefits would you highlight from using SF3D?

Something that surprised us a lot about this feeder is its operation since it is a very simple hopper to use. We control the feeder with slight exertion and minimum feed waste, something vital in the fattening phase. Another advantage of the SF3D is that regulation is minimal and very simple during the four months the pigs can be in the warehouse.

With the SF3D large animals can eat quietly without disturbing each other. Photo: Rotecna.

How is the adaptation of animals to the feeder?

In this warehouse, the pigs enter with a weight of between 18 and 22 kilos. In these large pens, animals enjoy a high level of animal welfare, but what is surprising is how quickly they understand where the food is, and acclimatisation is not a problem. The SF3D greatly facilitates the adjustment of animals, especially the first 30 days, because it allows pigs to access the feed easily and without complications.

Does it allow a good cleaning?

When cleaning the warehouse and all feeders, it is straightforward to clean the SF3D because it is a feeder with no complications or corners of difficult access for cleaning. In this way, with the system we use, the cleaning time and especially the final results, are very satisfactory. With this, there are no dirty areas that would imply having to repeat the cleaning.”.

In addition to this feeder, what other products has Rotecna installed on the farm?

We have a significant part of the products from Rotecna’s catalogue. In this new fattening warehouse, we have installed polypropylene panels, which have helped us have a very versatile farm that is easy to clean. The warehouse always looks clean because the material benefits it and does not cause problems. Outside of fattening, in maternity wards, we have practically the entire range of Rotecna products: the floor, the heating plates, the PVC fences, the weaning feeders, the dispensers, etc.

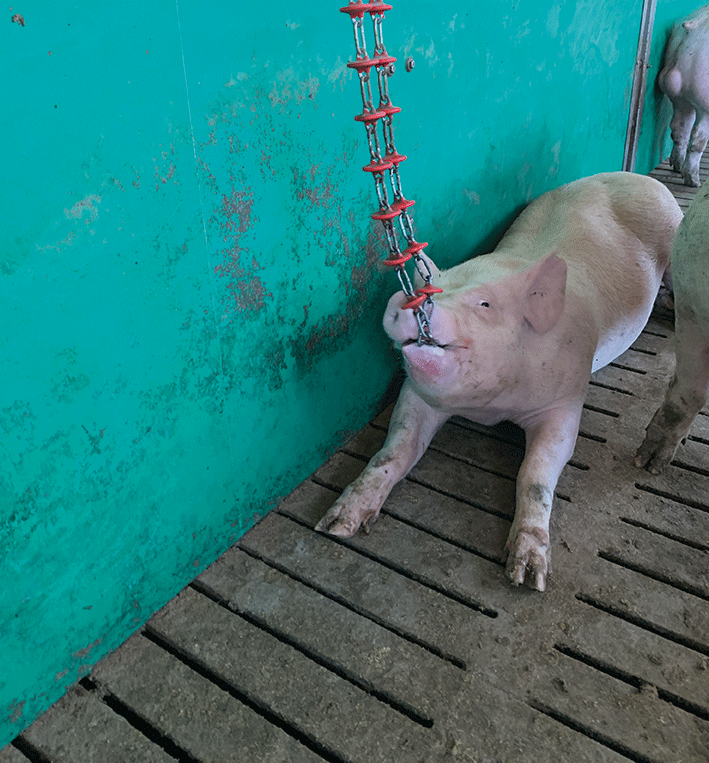

The room has manipulable material such as the anti-stress chain. Photo: Rotecna.

Overall, what do you value about Rotecna?

We have been working with Rotecna since its beginning. So, in addition to knowing all the products in its catalogue and the novelties that are coming out, we value the quality service it offers, the closeness with the people of the company, and the fact that, if there is any doubt or something to solve, they are immediately willing to answer.

Given the existing health threats, what biosecurity measures have you adopted on the farm?

We have biosecurity measures based on access control: dressing rooms at the farm entrance, clothes for exclusive use within the facilities. We try to apply everything we can within our needs. More can always be done, and we always look to implement that possible improvement, but we try to make everything that we do helpful.

At the health level, what are your main concerns?

The primary health problem that the sector has right now is African swine fever. Although it is a bit far away if we consider the particularities of our industry and the transport and movement of animals, the distance is not so much. There is also the PRRS that, although it seems dormant, is still there, and when it attacks, it is challenging to solve. Finally, any health problems wildlife may bring, for example.

What future challenges are there for the farm?

On our farm, we have many projects, but to carry them out, the budget must be right. One that is on the table and is already working on is making small extensions in the nucleus of sows to be more competitive. In addition, my eldest daughter has decided that she wants to continue with our business and, when one more person enters, we have to increase the volume so that we can all live from what we enjoy.