Blog

Blog

Can we revalue the carcasses of pigs?

10th August 2021 - News

European legislation on animal by-products stipulates that the bodies of animals killed on farms due to pathologies other than spongiform encephalopathy (Category Two by-products), after heat treatment, may be used to manufacture other products as biofuels or fertilisers. Aware of the benefits this may entail, and the potential of pig carcasses, the 2nd Health Defense Association of Ejea de Los Caballeros (Zaragoza) promoted the Valporc project to reveal these bodies. We spoke with Pedro Angel Sanz, veterinarian of ADS 2, to learn more about this initiative.

What is the Valporc project?

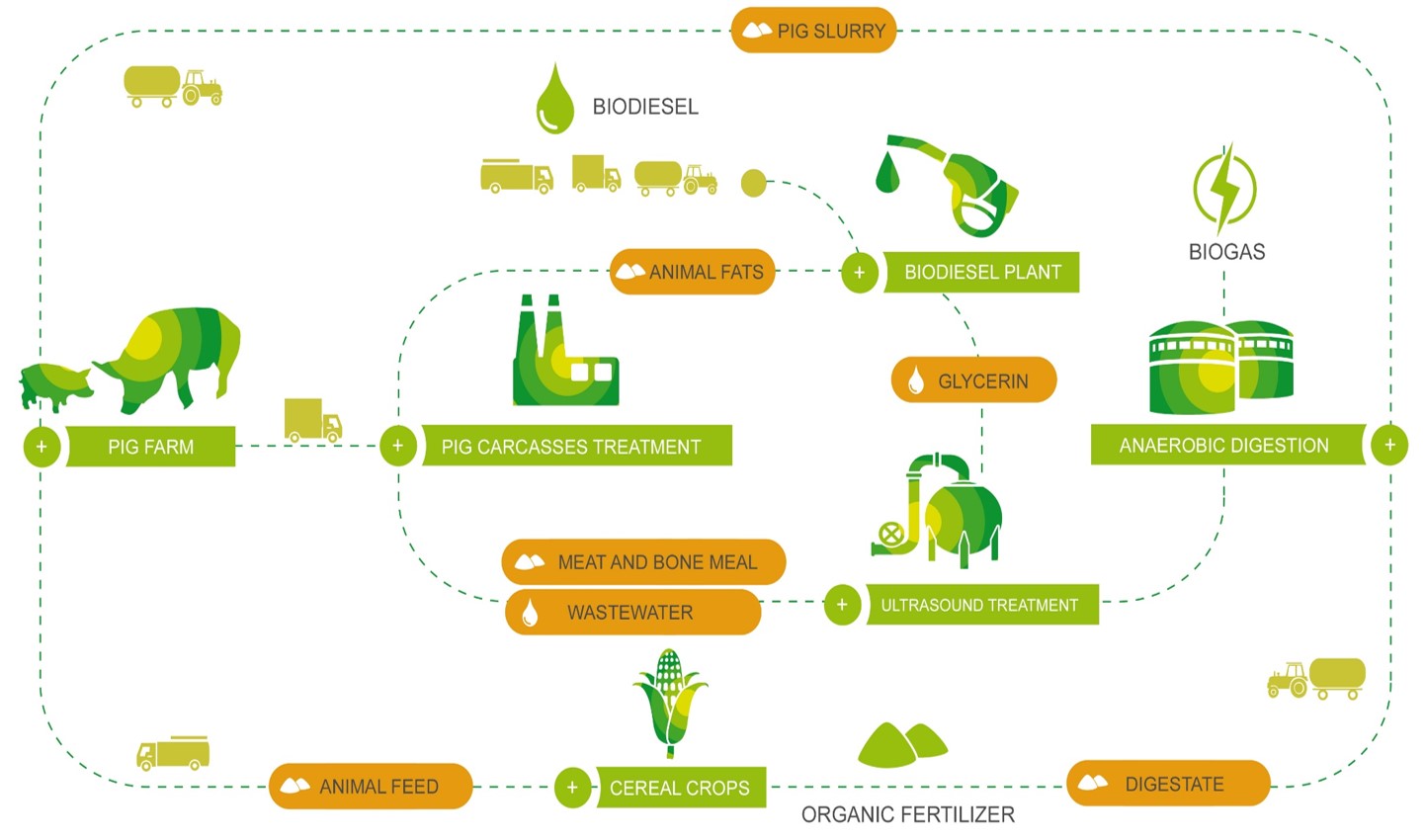

It is a project that aims to value pig carcasses, hence its name, and offer the sector an economical, sustainable and environmentally friendly alternative through an innovative treatment capable of converting the most polluting waste of livestock rearing, corpses and slurry, into high-value products such as biofuels and organic fertilisers. To achieve this, it is intended to take advantage of the corpse as much as possible and launch the most competitive technologies. In other words, we want to boost the circular economy and leverage the pig's corpse to extract biogas and biodiesel rather than burn it. So, we're going to achieve that the bodies are utilised to the maximum. The project, which began in 2014, has had a budget of two million euros, financed 50% by the European Union. The project partners have provided the rest: Cartif (Valladolid), Oleofat (Navarra), Energygreen Gas Almazán (Soria) and ADS 2 Porcino (Zaragoza), who spearheaded the project.

Specifically, what are the biofuels that can be obtained from the corpses of pigs?

We can get biogas, which is an alternative to natural gas, and second-generation biodiesel. Unlike first-generation biodiesel, which is obtained from plant crops, the second generation comes from animal carcasses and other non-plant sources. This is an advantage, as this type of biodiesel does not compete with human food and reduces biodiesel production costs in general. Finally, usable meat flour can also be obtained to improve the quality of the slurry.

Since the beginning of the project, they have carried out several pilot tests. What have they consisted of?

We have done tests in which all the project partners have participated. All the cadaver fats possibilities and the technologies to be applied for high-quality biofuels have been tested. Many tests have also been carried out in meat flours to achieve the best way to acquire an optimal product. Thus, the recovery process begins at an Energygreen Gas Almazán pilot plant with the capacity to handle 3,500 tons of pork. The crushing and sterilisation of the corpse is carried out here, processes by which two by-products, meat flour and fats, are obtained. Flours are used to secure biogas by applying an innovative technology by ultrasound, with which we get electrical and thermal energy in a much more environmentally friendly way. In addition, there has also been a demand for this meat flour to be used as the basis for different fertiliser products. On the other hand, fats are taken to Oleofat, where they are treated to become biodiesel. In Cartif, tests have been carried out to optimise cavitation biodiesel and biogas production by anaerobic digestion in two phases. The whole process has required much work, time and significant participation, as it is very novel.

How does the Valporc project contribute to the preservation of the environment?

In a very positive way, as it contributes to the circular economy. Currently, the corpses are burned and used as a source of heat. However, incineration generates ashes that must then be buried, which is a deterioration for the environment. With the Valporc project, a corpse can become a fertiliser that will later go to the field, and no ash is generated, which improves the environment. On the other hand, generating more sustainable biodiesel also reduces emissions of polluting gases, as it avoids the use of fossil fuels. Thus, the benefits are several and come from all the products obtained and harnessing the corpse's potential. As for the farmer's pocket, the project proposes a reduction in the cost of managing corpses. Incineration plants charge a certain amount that could now be reduced or even reach zero if the product's price offsets that process.

Does the construction of plants capable of performing this whole valorization process require a significant investment?

Yes, about five million euros. We initially thought about the possibility of building such a plant in Ejea de Los Caballeros, even bought a plot to install it, and spoke to entities and companies. However, in the end, the idea was not carried out because of the very high investment it requires and the impossibility of obtaining capital at the time.

What challenges does the Valporc project now pose?

The main challenge is to continue to have funding to continue its development. It is a project that we believe can be pretty successful. However, people are already interested in it since the products generated from the revaluation of corpses have excellent market access. Moreover, the primary resources required, slurry and corpses, are always available, so its feasibility is guaranteed.