Blog

Blog

Ramgerpig: "With Dositronic we notice a weight gain in the piglets"

29th September 2022 - Success stories

Ramgerpig is a family livestock company in Solsona (Lleida) that has different sow farms with 2,800 stalls, besides 11,000 fattening stalls and another 16,900 integrated stalls. For a few months they have opted, with excellent results, to work with the Dositronic electronic feeding system in farrowing wards. That is why we spoke with Albert Pijuan who, together with his cousins, is the fourth generation of the family that continues with the pig farming trade.

What is the origin of the farm?

This farm has grown depending on family financial availability. In 1988, they built a first phase comprising 300 sows, which in a few years was expanded to 500 sows. Later, in 2004, we reached 1,000 sows and, finally, in 2021, we made the last expansion until we reached the 1,600 sows that we currently have. We should note that this has always been a farm in Phase 1 and Phase 2. We have 11,000 own fattening stalls, and we have another 16,900 integrated fattening stalls. In addition, we are a company that is characterised by having its own multiplier. We produce conventional pork and also ‘Ral d’Avinyó’ quality pork.

How is the farm arranged?

We have a quarantine area, about 500 meters from the farm and with a capacity to accommodate 200 gilts. This area is filled every two months with an all-in-all-out system. Then there is the mating-control area with 480 cages, the gestation park area, where we have several warehouses with semi-box pens and, since the last expansion, we have a warehouse with 360 self-capture cages. We have the farrowing unit with 364 places, of which 112 are free farrowing units adapted to animal welfare and have the Dositronic electronic feeding system installed. Finally, we have a transition of 4,500 places.

Who works on the farm?

Seven people work intensive hours and one of them is in charge of maintenance.

Why did you decide on the Dositronic electronic power system?

We decided on this system in order to optimise the sows’ consumption throughout lactation, besides individualising the number of feeds, as well as their schedule.

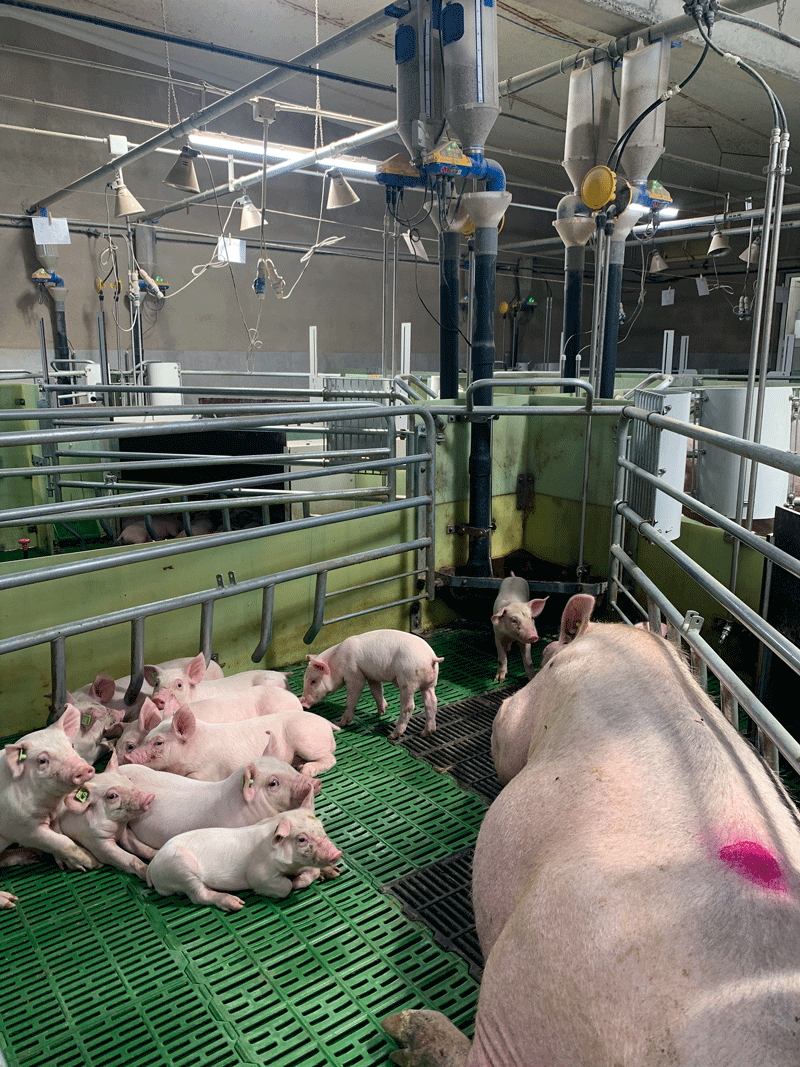

Image of a farrowing pen with Dositronic M. Photo: Rotecna.

What benefits would you highlight from using Dositronic?

It is a system that allows us to reduce feed waste; it is a very practical, simple and intuitive system for the breeder. We also value that we can change the individual ration of each sow from the device itself and that for us it represents a very significant reduction in the workload on the farm. Finally, we consider it to be a very good value for money option.

How many power curves do you work with?

On this farm, we are currently working with two feeding curves, one of them adapted for nulliparous sows and another curve for the following deliveries. The frequency of administration in both curves is five daily doses with two schedules: winter and summer.

How is the feed handling with the Dositronic?

Our daily work with the Dositronic consists, first, of looking at all the sows that have not had optimal consumption on the computer, and then going inside the rooms and changing the individual ration of the sows based on the colour that the Dositronic control panel says.

What does it mean to have all consumption data computerised?

In our case, it allows us to know each sow’s real consumption throughout lactation, see its loss of body condition and be able to implement individualised feeding curves for each sow.

Albert with the Dositronic management program. Photo: Rotecna.

At the productivity level of the sows and the litter, have you noticed improvements?

Because of a higher feed consumption of sows thanks to Dositronic, we have noticed a significant increase in the piglet’s weight at weaning. Regarding the productivity of the sows, we have noticed an improvement in their body condition at weaning and a decrease in the weaning-covering interval, which is a highly important factor in prolificity at the next farrowing.

Besides Dositronic, what other Rotecna products do you have installed on the farm?

We have several Rotecna products: hoppers, dispensers, drinkers, drag systems, slats and many others.

What do you value about Rotecna?

What we value most is that it provides us with products that are exceptional value for money and offers practical, simple and very easy-to-clean products. Finally, we want to highlight the care, proximity, and attention of their technical and commercial departments towards their clients.

What are your primary concerns at the health level?

As in the entire industry, the primary concern at the health level is the African swine fever (PPP), and in the particular area, currently, what concerns us most is the PRRS. Fortunately, so far we have stayed away from the new strains of this virus.

What biosecurity measures do you take to reduce the risk of disease transmission?

We believe that the greatest biosafety measure is to have our own multiplier that allows us to ensure that the origin of our replacement is always the same and with a known health status. In addition, we have an external quarantine with exhaustive biosecurity measures, a carcass container far from the farm with a separation between clean and dirty areas, our own transport without contact with any slaughterhouse and external loading docks. It should also be noted that our farms are in an area of low pig density such as Solsonès.

What future challenges arise for the farm?

Our challenges are always directed towards better biosecurity and implementing process automation, which allows us to reduce the workload, improve competitiveness and reduce costs. In this sense, of the 364 farrowing stalls that we have on this farm, 150 already have the Dositronic electronic feeding system and, in the coming months, one of our challenges is that we implement this system in all farrowing pens.