Blog

Blog

Selecting the Fans for Swine Barns: A Comprehensive Guide

03rd July 2024 - News

Marcel Weiss Hoffmann. Munters Sales Area.

The requirements for pig producers to increase animal welfare and achieve a successful result are becoming more demanding. Improvements in nutrition and genètics and the need to control the environmental aspects inside a swine barn are becoming more relevant to be able to achieve good production results.

In swine farming the importance of climate control has many aspects. In previous articles topics as Inlets, filtration, evaporative panels, and Controllers were explained. For this text, the focus is on the ventilation. Inside the pig farms it is necessary that the circulation and air renewal be adequate to eliminate excess heat, humidity and odors. Insufficient ventilation can lead to poor air quality, which can adversely affect the health of the pigs and the farmworkers.

It is important to correctly select the fans to be installed, since it is what will generate all the ventilation inside the air-conditioned barns. There are several factors that farmers need to consider for proper fan selection. Minimum ventilation, which maintains air quality, allows you to reduce heating and energy costs. Meanwhile, maximum ventilation also eliminates all additional heat and keeps the animals at a comfortable comfort level. The fan needs to be capable of working for long periods, resisting the challenges that exist in swine barns.

The first basic consideration that needs to be considered on a fan is its hability to work in an environment with dust and ammonia. Therefore, products that are designed to work in these environments have a longer durability and are more reliable. There are options with special material. Exhaust fans with Stainless steel, plastic, or innovative solutions as the Munters Protect can give a great return on the investment made.

Ventilation capacity is another important aspect that needs to be considered. This subject requires an understanding of the needs for the installation. This can be a fan with low airflow capacity that will be used for minimal ventilation or high airflow fans, for projects that require large amounts of air extraction. Its critical to make a selection that allow to reach all needed ventilation, both minimum and maximum. The capacity to make a smooth transition from ventilation levels are also relevant to product selection. This avoid wastes (of energy , heat) and allows the proper conditions for animals during all ventilation stages during day and night, all year.

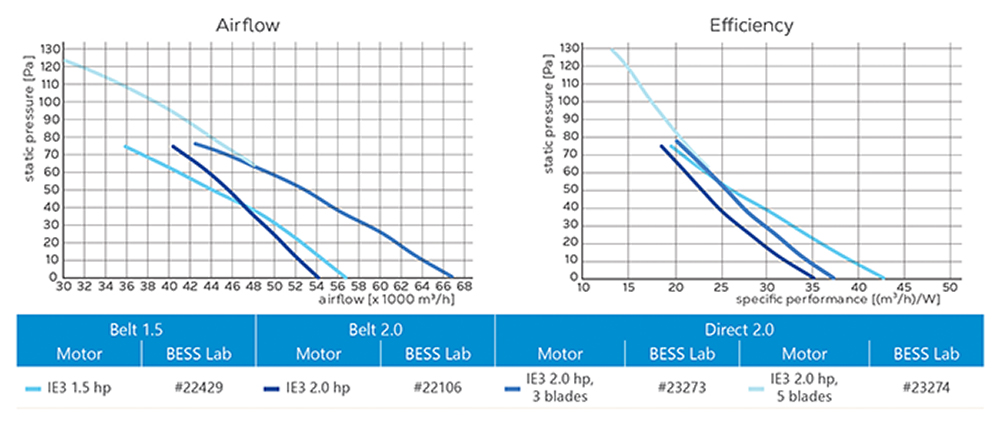

The capacity of the fan have a relation to the environment that it will be used in. Considering the pressure drop that the fan needs to be able to work is mandatory on a good selection. Fans have different air flow, and power consumption according to the pressure drop. Its common in the market to use a third party measurement of the fans to be able to compare different brands and equipments. Follow an example of the same fan being tested with different motors and different set of Fan propeller blades. The results vary and depending of the requirements od the installation the suggest equipment can change.

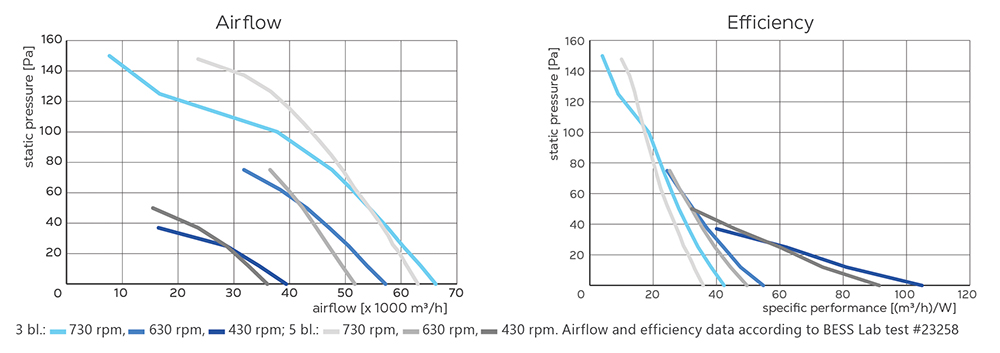

In variable speed fans, having access to the fan curve can result on an optimal solution for reducing energy consumption, and adjust the ventilation level that is needed for the animals. The following example have the same fan with an electronic motor with variable speed.

It is important to obtain information from a reliable source: not just the ventilator manufacturer, but a test that allows you to compare the equipment and ensure that the animals will have what is expected once the systems are installed. Details can have a significant impact on the fan capacity, as changes from single phase or 3-phase motors or 50 Hz to 60Hz. For this examples, the reference is the BESS lab. Each test have its on reference number that can be consulted and all characteristics of the test will be informed.

As swine farming operations expand, the fans system should be able to scale accordingly. The equipment’s should be compatible with the installation and controllers that are going to be used. Maintenance needs to low , be easy and cheap. The fans that demand small amounts of labor to be maintained, and suppliers with history of offering spare parts are important criterias on the selection.

Energy efficiency is a common topic that is vital for the farmer. Having the correct product for the farmers’ condition can result in substantial savings on energy costs. For some projects more than 70% of all energy consumption is related to exhaust fans. Selecting the fans that are most efficient in the working condition is necessary. In this subject, the use of some electronic motors has being demonstrated great improvements. Calculations of “Total Cost of Ownership” considering the cost of acquisition of the fan and the cost with maintenance and energy consumption over the years, are demonstrating every day that is worth the investment.

As for other aspects, communication is also becoming more important for fans. Some fans are allowing communication to increase software programs, make new regulations or having feedback on motor parameters as temperature and rotation. Features like this , allow for exemple preventing actions and maintenance, reducing costs and avowing problems. This is a new trend and is worth looking for solution with communication features it to understand if can be beneficial on the business.

The costs associated with failures in ventilation systems can be high, therefore reliability and durability are non-negotiable traits. Swine farming is a demanding industry, and equipment failure can have severe consequences. Invest in fans from reputable manufacturers known for their reliability and longevity are critical to minimize the risks and have peace of mind.

With decades of experience and worldwide expertise Munters evolved its equipments and developed many options for the ventilation. Munters is transforming the swine business, taking it to the next level with Chimneys , Eletric motors and all sorts of solutions that can be used. It can fit all aspects of the farm’s needs, achieving the best air quality and animal welfare as possible while using the less environmental resources. Modern swine farms demand constant optimization and streamlining of production in accordance to animal’s growing stages. Munters expertise on ventilation system, ensures perfect climate conditions and fast response to weather changes, while reducing energy consumption and carbon footprint.

In conclusion, selecting the right ventilation for swine barns requires a comprehensive understanding of the specific needs of the animals and the farm's operational requirements. Farmers should prioritize exhaust fans that offer precise control, efficient ventilation, user-friendly interfaces, reliability, and energy efficiency. By investing in high-quality systems, swine farmers can create an optimal environment for their animals, leading to healthier, more robust pigs and ultimately, a successful and sustainable farming enterprise.